For the Love of Maple

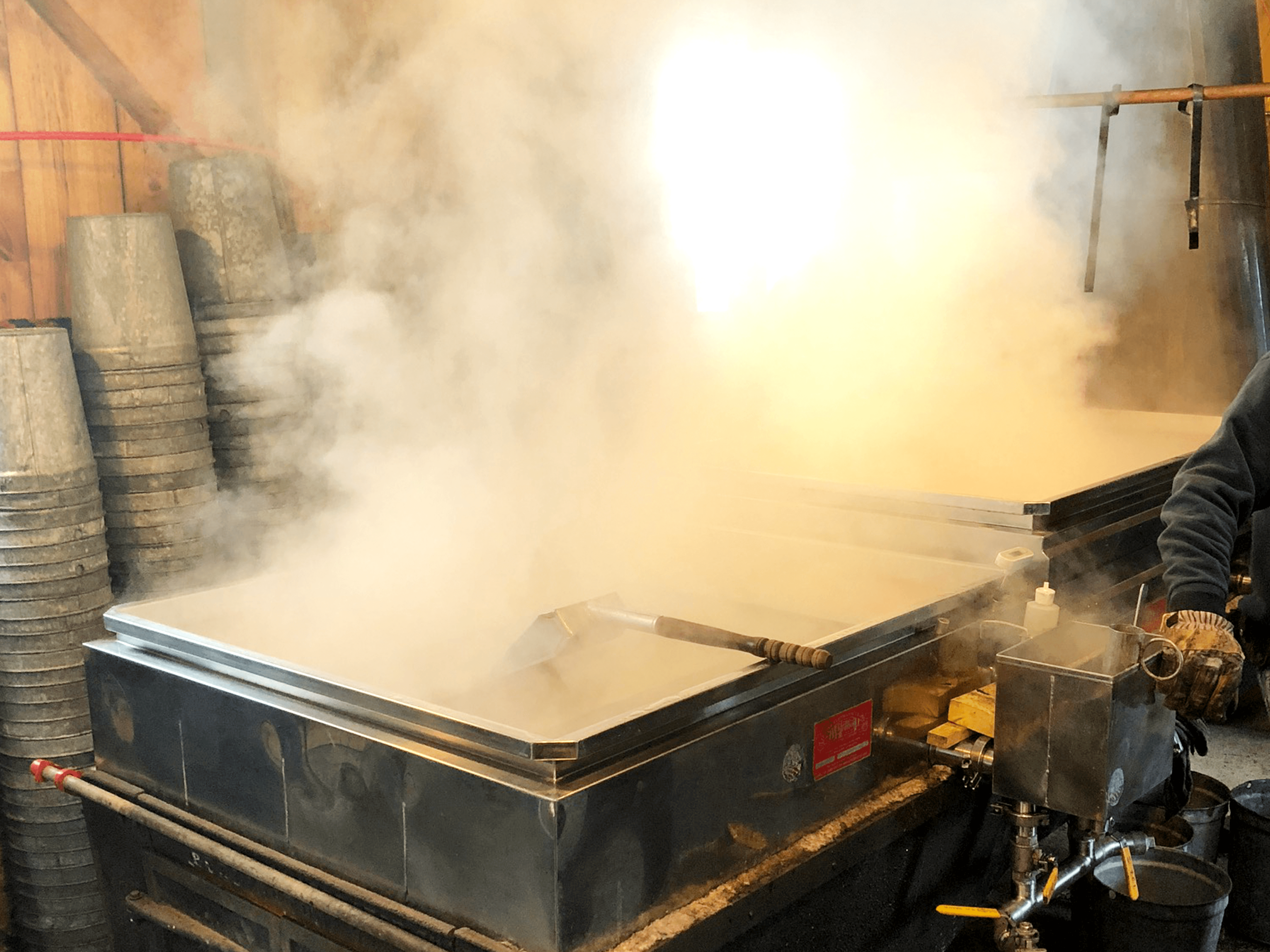

I’ve fallen in love with maple syrup. Everything about it attracts me. The quaint sugarhouse covered with snow, the “ping, ping” of sap dropping into the sap bucket, the crackling fire under the steaming evaporator. The smell of transformation during sugaring season. The sweet, tantalizing taste. Just everything.

One can only imagine the time and dedication it takes to be a maple farmer. I didn’t grow up in the industry, but on a recent trip to Vermont and New Hampshire for research on a new project, I had the honor and pleasure of meeting someone who has. Arnold Coombs is a 7th generation sugar maker. His family company, Coombs Family Farms, and their parent company Bascom own 10% of maple syrup sales worldwide. When you talk to Arnold, you get the feeling you can’t stump him if you wanted to. If it has to do with maple, there’s nothing he doesn't know.

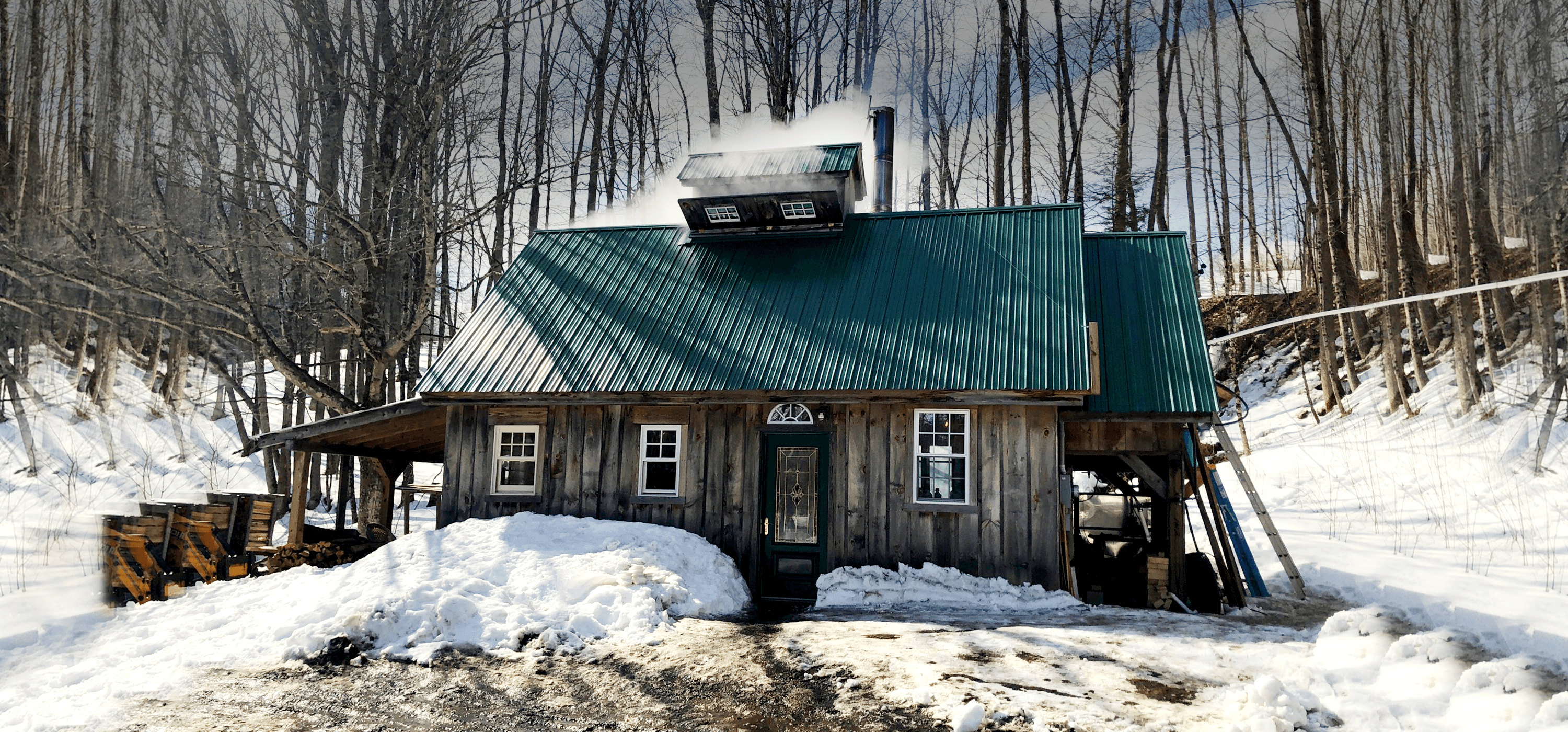

When I first came upon Arnold’s family sugarhouse in Vermont, I felt like I was in a Norman Rockwell painting. It was homey and cozy and just the type of place where you’d like to spend a Sunday. The steam was billowing from the open windows, escaping from every pore. Inside, it was like a sauna. The two men running the place, Arnold’s cousin Ted and another gentleman, were friendly and full of information.

Did you know that lighter syrup is made in the early spring? That’s because the sap has more sugar (roughly 2%) and it’s boiled for a lesser period of time. Later in the season, the sap has less sugar (about 1.5%) and you have to cook it longer, resulting in a darker color. The lighter syrup has a delicate taste and the darker syrup is richer, but both are equally delicious. Just depends upon your preference. Interestingly enough, coming out of the tree, it all tastes like water.

Also, I’m not sure how much you know about reverse osmosis, but it changed the maple syrup industry. Reverse osmosis removes ions, particles and molecules from drinking water; when applied to syrup, it concentrates the sugar to reduce the boiling time needed to make maple syrup. Arnold took us to the large Bascom facility in Alstead NH, where they have an RO machine that concentrates the sap from 2% to 20% sugar. Amazingly, it usually takes 43 gallons of sap to produce one gallon of syrup, and the RO machine concentrates the sap so much that takes just four gallons of sap to produce one gallon of syrup. It’s crazy efficient.

All of this means lesser impact on the environment, from a fuel efficiency standpoint. What used to take four gallons of fuel to get one gallon of syrup now takes ¼ gallon. Coombs Family Farms and Bascom are serious about the environment and sustainable sourcing. Arnold told us they have phased out the metal taps and replaced them with plastic ones, which are better for the trees because they reduce infection around the tap site.

He also showed us the miles and miles of tubing used at the Bascom facility. The tubing is all tied into a central line that uses a vacuum to suck out the sap. We met Bruce Bascom, who helped improve the tubing systems and pioneered the use of reverse osmosis machines. He had the first in the maple industry.

Bascom also buys maple syrup from over 3,000 family farms. A sugar maker can drive in at any time no appointment needed, hand in barrels of syrup and get paid in the same day. This is unusual in the industry, and just another reason the company sets themselves apart. At other places, you have to make an appointment and you don't get paid for a week. For a small farmer, this is a huge deal.

Through all of this and more, Arnold shared with us his passion and his history. I learned as much about him as I did about maple syrup. Honestly, this was more than an educational trip. It was about understanding the philosophy of a large company that acts like a small family. Bascom may be the leading supplier of maple syrup in the country, but the distinction is their mindset. I felt an immediate connection, something that resonated, a feeling of belonging. It’s a business of passion, of honesty, of an unparalleled genuine nature. It’s realness in every sense of the form, from the product to the people. And that has made all the difference.